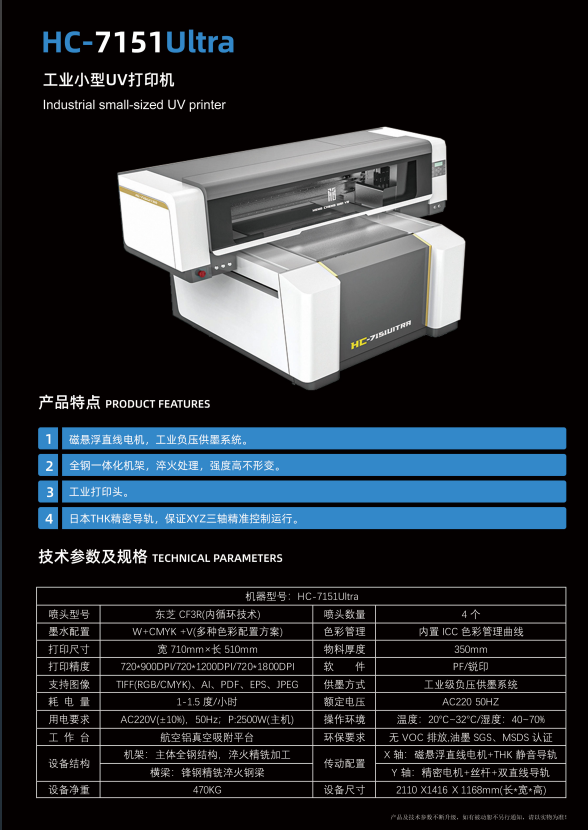

7151視覺打印機具(jù)有(yǒu)高精(jīng)度和多(duō)種适用(yòng)場景的優勢。以下是具(jù)體(tǐ)優勢:

高精(jīng)度打印:7151視覺打印機采用(yòng)高精(jīng)度視覺定位打印技(jì )術,能(néng)夠提供高質(zhì)量的打印效果,滿足高精(jīng)度打印需求。

适用(yòng)多(duō)種機型:該打印機适用(yòng)于6090、9060、7151等多(duō)種小(xiǎo)機型,具(jù)有(yǒu)廣泛的适用(yòng)性,能(néng)夠滿足不同用(yòng)戶的需求。

高效穩定:7151視覺打印機采用(yòng)先進的打印技(jì )術和穩定的性能(néng),能(néng)夠實現高效穩定的打印效果,提高工(gōng)作(zuò)效率。

多(duō)種标準認證:該打印機符合多(duō)種國(guó)際标準和認證,如VCCI A級、FCC A級等,保證了産(chǎn)品的質(zhì)量和可(kě)靠性。

綜上所述,7151視覺打印機以其高精(jīng)度、多(duō)種适用(yòng)場景、高效穩定以及多(duō)種标準認證等優勢,在市場上具(jù)有(yǒu)較高的競争力。

18566665472

18566665472